Why Rapid Prototyping is so important for Product Design?

Rapid prototyping is a crucial aspect of product design, offering a wide range of benefits for designers, engineers, and businesses. This process allows for the quick and efficient creation of physical models of design concepts, enabling early validation, testing, and modifications. By utilizing rapid prototyping, product design can be streamlined, reducing the risks and costs associated with launching a new product. In addition, the ability to quickly visualize end products and receive feedback from stakeholders greatly improves the chances of success.

It’s clear why businesses seek rapid prototyping in product design, as it offers numerous benefits, including improved accuracy, reduced time-to-market, reduced costs, improved design outcomes, stakeholder engagement, testing and validation, increased flexibility, and competitive advantage. Optimize your product design process by exploring the benefits of rapid prototyping today.

Types of Prototypes

There are several types of prototypes that can use in the product design process. Each of them with its own unique set of benefits and limitations. The most common types of prototypes include:

- Concept models or sketches – simple hand-drawn or computer-generated representations of a design idea

- Virtual prototypes – computer-generated models that simulate the functionality and behavior of a product

- Physical prototypes – tangible models that represent a product’s size, shape, and form

- Proof-of-concept prototypes – prototypes that demonstrate a product’s viability and prove its underlying technology or design concept

- Functional prototypes – prototypes that mimic the intended functionality and performance of a product

- Appearance prototypes – prototypes that focus on the product’s physical appearance and surface finish

- User experience prototypes – prototypes that simulate the user’s experience and interaction with a product

Each type of prototype serves a different purpose in the product design process. Each type can use at various stages of development, from ideation to testing and refinement. The specific needs of the project, the design goals, and the available resources will determine the type of prototype chosen.

What is Rapid Prototyping

This is a process of creating physical models of a product design quickly and efficiently. It is a key step in the product design process and enables designers and engineers to;

- Validate their ideas

- Test functionality

- To make any necessary modifications early on.

Rapid prototyping streamlines product design by producing prototypes quickly, allowing for early testing and feedback. The process uses technologies like 3D printing, CNC machining, and vacuum casting to create prototypes with high accuracy and realism. The goal is to reduce costs and risks, improve chances of success and speed up the product design process.

The Basics of Rapid Prototyping and How it Fits into the Product Design Process

This is a critical part of product design, allowing for the creation of physical models of ideas quickly. It follows conceptualization and design, before mass production, and starts with a digital design for physical prototype creation using technologies like 3D printing, CNC machining, or vacuum casting.

The goal of this technology is to validate the design concept and test the product’s functionality and performance. Other than those we can use them to make any necessary modifications early on. This helps to identify and resolve any issues before mass production, reducing the risk of costly errors and delays. It also allows designers and engineers to quickly iterate and refine the design, leading to improved design outcomes.

Rapid prototyping also provides stakeholders with a tangible representation of the product, enabling them to visualize and understand the design. This can help to secure buy-in and support from key stakeholders. This can also lead to valuable feedback and insights that can be incorporated into the final design.

Overall, rapid prototyping fits into the product design process as a crucial step. That streamlines the design process, reduces risks and costs, and improves the chances of success.

The advantages of using rapid prototyping in product design

Rapid prototyping offers several advantages in product design, including:

- Improved Accuracy: Rapid prototyping validates design quickly and accurately, reducing errors and rework.

- Reduced Time-to-Market: Rapid prototyping speeds up a time to market.

- Reduced Costs: Rapid prototyping allows designers and engineers to identify and resolve any issues early on, reducing the risk of costly errors and delays in the mass production phase.

- Improved Design Outcomes: Rapid prototyping enables designers and engineers to quickly iterate and refine the design, leading to improved design outcomes.

- Stakeholder Engagement: Providing stakeholders with a tangible prototype helps secure support and provides valuable feedback for the final design.

- Testing and Validation: Rapid prototyping allows for early testing and validation of the product design, enabling designers and engineers to identify and resolve any issues before mass production.

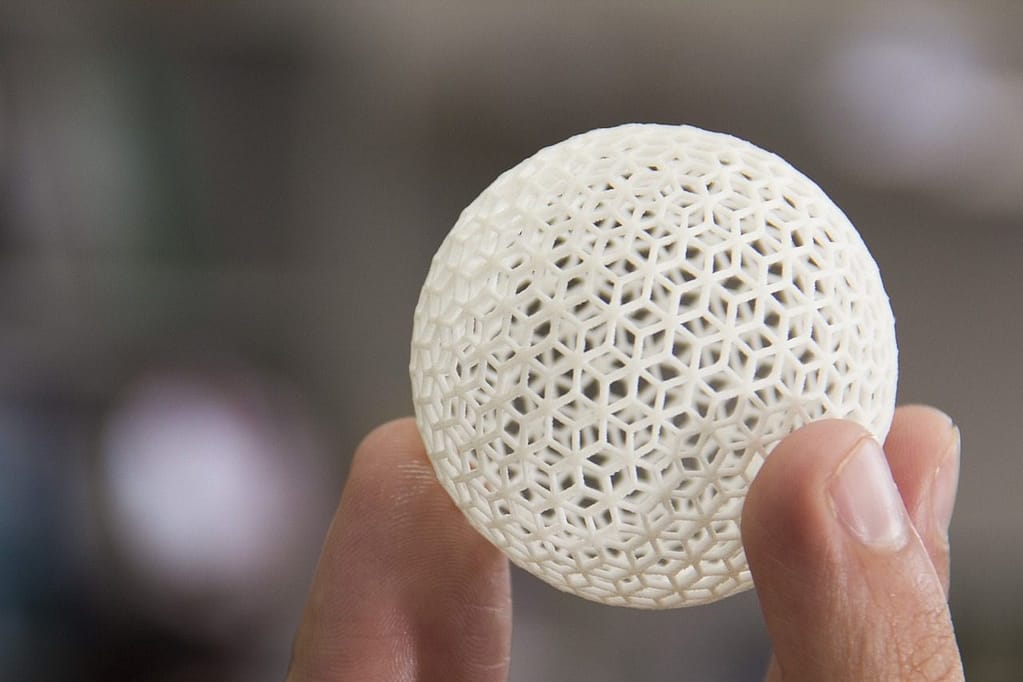

- Increased Flexibility: Rapid prototyping technologies offer a high degree of flexibility, enabling designers and engineers to quickly create prototypes of different shapes, sizes, and materials.

- Competitive Advantage: Companies that incorporate rapid prototyping into their product design process have a competitive edge, as they are able to bring products to market faster and with improved accuracy.

In summary, the use of prototyping in product design offers a range of benefits, including improved accuracy, reduced costs and time-to-market, improved design outcomes, and stakeholder engagement.

Different Types of Rapid Prototyping Technologies

There are several types of rapid prototyping technologies, including:

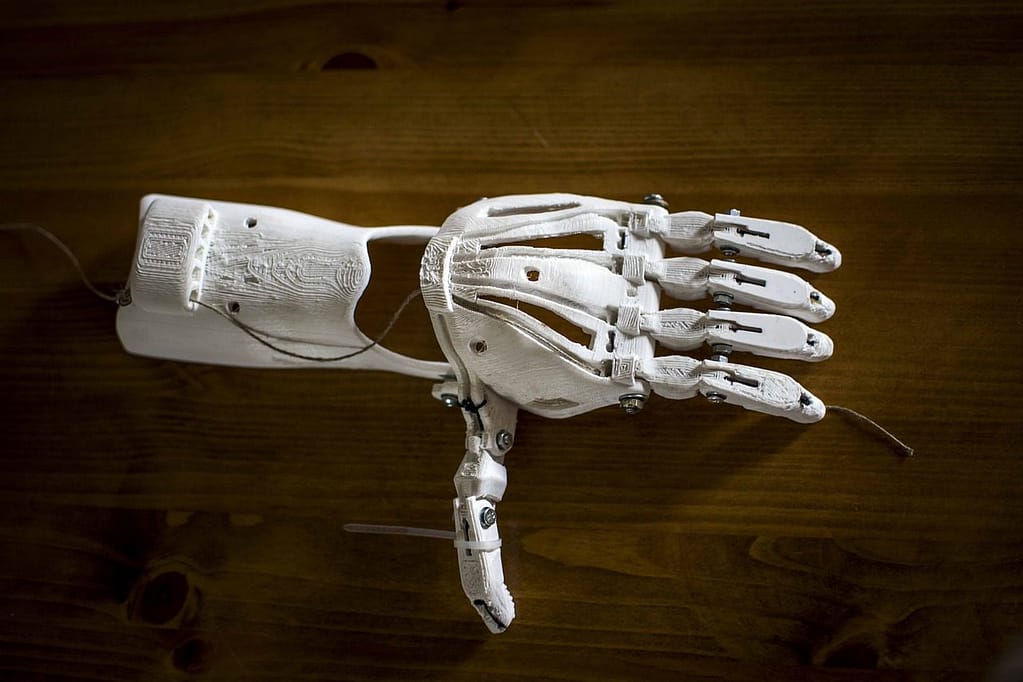

- 3D Printing: This technology uses a printer to build a physical model layer by layer from a digital design file. 3D printing can produce prototypes in a range of materials, including plastics, metals, and ceramics.

- CNC Machining: This technology uses computer-controlled tools to carve a physical model from a solid block of material, such as metal or plastic. CNC machining is often used to produce prototypes with high levels of accuracy and detail.

- Vacuum Casting: This technology uses silicone molds to produce multiple copies of a prototype. the master model that creates the molds.

- Stereolithography (SLA): This technology uses a laser to cure resin into a solid object layer by layer. SLA is often used for prototypes with complex shapes and intricate details.

- Selective Laser Sintering (SLS): This technology uses a laser to sinter powder materials, such as nylon or plastic, into a solid object. SLS is often used for prototypes that need to be functional and durable, as well as aesthetically pleasing.

- Fused Deposition Modeling (FDM): This technology uses a heated extruder to build a physical model layer by layer from a digital design file. FDM is often used to produce prototypes with large parts and simple shapes.

These are some of the most commonly used technologies. The choice of technology will depend on the specific requirements of the project, including the type of material, accuracy, and speed needed.

The Future of Rapid Prototyping in Product Design

The future of rapid prototyping in product design is bright, driven by technological advancements and increased demand for efficient and cost-effective product development. Key trends include improvements in 3D printing, increased use of multi-material printing, advancements in VR and AR, greater adoption of cloud-based technologies, and a focus on sustainability. These advancements will lead to more accurate and realistic prototypes, faster design processes, and increased collaboration between designers and engineers. With these exciting developments in rapid prototyping, product design will continue to evolve and improve in the coming years.

Thank you for reading our article on the importance of rapid prototyping in product design! We hope this piece has shed light on the significant role that rapid prototyping plays in the development and success of innovative products.

Feel free to explore our website or reach out to us directly for more information on how we can support your product design journey.

0 Comments