CNC and NC Machines for Industrial Applications

NC machines and CNC machines refer to numerical control machines and computer numerical control machines, respectively. For jobs requiring precision and pre-defined dimensions, NC and CNC machines can use. The collection of instructions used to drive numerical machines takes the form of letters, numbers, and symbols. Punch cards and other methods were used to feed such instructions into the machine.

Computer Numerical Control machines that use computers, or CNC machines, can perform more complicated operations than traditional numerical control machines. For moveable machining operations involving three to several axes, CNC machines are frequently employed. Computer software is typically used to generate programming or work instructions, which are input directly into CNC machines.

Overview of CNC and NC Machine

There is a very nice history of CNC and NC machines. there are several applications in which CNC machines are essential.

History of NC Machines

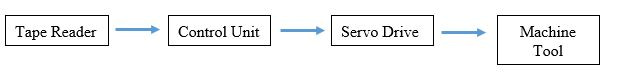

When researching the history of the NC machine, Jone T. Parsons developed a method to control the machine tool using punch cards in 1940. After the first demonstration, a commercial NC machine was launched in 1952. Numerical machines are programmed with a set of instructions that take the form of letters, numbers, and symbols. Punch cards are used to power NC machines. NC Machines contain some fundamental components.

For the NC machine, we need to provide control information, and the MCU (Machine Control Unit) and Machine tool will be doing the job according to the control information.

Characteristics of NC Machine

- Numerical control machine

- Not a Software Driven Machine

- Can’t use the CAD (Computer Aided Design) Files

- Operation parameter can’t change

- The machine can’t run continuously

- It stores in punch card memory

- Less flexibility or computational ability

- High-skill operators need to operate NC machines

- Less maintenance compared to CNC machine

- Less maintenance cost

- The cost of the machine is less compared to a CNC machine

- Modification of the program is very difficult

- It offers less flexibility and computational capability

- The degree of accuracy is less compared to CNC Machine

- Less capable of multiple programs storing

- Unavailability of Online flatforms

- Less use of advanced interpolation

- Unavailability of Automatic tool compensation

- Unavailability of auto-generation of NC programs

History of CNC Machines

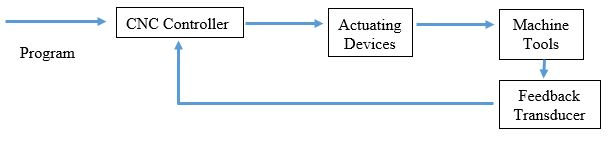

There are some significant elements in CNC (Computer Numerical Control) Machines due to these machines are been designing to do multiple operations at once.

In CNC machines there must have the hardware, software program, and statistics to do the machining operations. the primary hardware is Microprocessor and so one can manage function and peripheral communication between gadgets. other than these things machine device repute tracking and tool interfacing are a few crucial features.

software is an important and sizeable characteristic of the CNC gadget. There are special kinds of software programs which are CAD-associated software programs and Machining functioning software. That is executed by means of device microprocessors.

Characteristics of CNC Machines

- CNC Machines

- Computer Numerical Control Machine

- Software Driven Machine

- Can use and import the CAD Files

- Operation parameters can change

- 24 hours continuous operation is possible

- Directly use the computer’s memory

- Flexibility is very high

- Semi-skill operators can run the machine

- High Maintenance

- High Maintenance cost

- Cos of the machine is high

- Easy to modify the program

- It offers additional flexibility and computational capability

- High accuracy and micro level machine is possible.

- Multiple programs storing capacity

- Online part programming and editing

- Use of advanced interpolation

- Automatic tool compensation

- The part program is automatically generated for existing components.

Basic Elements of the CNC Machines

There are general input devices such as punch tape readers, and magnetic tape readers. The CNC Machine’s driving system, which consists of electronic equipment circuits, drive motors, and ball lead screws, as well as the feedback system, is constantly monitoring the position and speed of the cutting tools.

Types of CNC Machines

There is plenty of a different kind of CNC machine according to the applications and industrial requirements. Similarly, Sometimes industrial designers and mechanical engineers tend to develop some machines in-house for in-house requirements. Using stepper motors, motor controllers and G-codes helps them to develop custom CNC machines. However, today’s CNC technology and machine are drastically developing with custom designs. Additionally, we can find more axis of rotations for instants 3-axis, 5-axis and 6-axis CNC machines don’t only milling there is CNC welding machine also.

- Milling CNC Machine

- Lathe CNC Machine

- Drilling CNC Machine

- CNC Laser Cutting Machine

- CNC Plasma Cutting Machine

- EDM Machine

- CNC Router Machine

- 3-D Printers Pick and Place Machines

- CNC Welding Machine

- CNC Winding Machines

- Core Cutting Machine in Transformer Industry

- Painting Machine in Automobile Industry

Above all are common industrial CNC machines. But Core cutting machines, CNC winding machines, and CNC printing machines in appeal industries are somewhat custom-oriented machines. All the designers and engineers have the freedom to design and developed their own CNC machines.

CNC Milling Machine

CNC milling is a machining process that uses computerized controls and rotating multi-point cutting tools to remove material from a workpiece and create a custom-designed part or product. This process is appropriate for machining a variety of materials, including metal, plastic, glass, and wood, as well as producing a variety of custom-designed parts and products. There are various types of CNC Milling machines and various types of milling operations. CNC Milling machines can use for lather, drilling, and surfacing operations as well.

Milling began as a manual task performed machine by humans. But most milling today is been performing by a CNC mill, which uses a computer to supervise the milling process. Although CNC milling provides greater precision, accuracy, and production rates, manual milling is still useful in some situations.

Operations of CNC Milling Machine

Normally CNC milling is a machining process used to create high-accuracy, high-tolerance parts and another purpose is to get a high production rate. CNC Milling operations can use for one-time jobs like prototypes, one-offs, and small to medium production runs. there are different kinds of basic milling operations that we can use for machining. The followings are some of the basic milling operations.

- Face Milling

- Angular Milling

- Plane Milling

- Form Milling

Other than these milling operations we can use the milling machine for the following operations as well.

- Slot Milling

- Threading

- Saw Milling

- Gear Cutting

- Cam Milling

- Milling of Keyways, Grooves, and Slots

- Straddle Milling

Face Milling

Face milling is the most simple milling operation in a CNC milling machine and is widely used to prepare a flat surface perpendicular to the mill cutting axis. depending on your CNC machine and the machining requirement vertical or horizontal milling operations are possible.

Form Milling

Form milling operation helps to machine curves and straight lines in a single cut. Formed cutters can use for vertical and horizontal milling machines and can ground to the contour of the workpiece. The contour is sometimes ground with a single-point fly cutter.

Types of Milling Cutters

When you are finding milling cutting tools you will find a pool of cutting tools. That is because Milling cutters are playing a major role in milling operations and there are various different types of milling cutters. Cutting tools are of numerous sizes and shapes according to the requirements. The followings are the common examples of milling cutters.

- Face milling cutters

- Slab mills

- End mill cutters

- Ball mill cutters

- Thread mill cutters

- Fly cutters

- Dovetail cutters

- Side milling cutters

- Helical plain milling cutters

Really appreciate you, taking the time to read the article about CNC and NC Machines. Furthermore, we will discuss Milling tool types, their applications, and selection criteria. Other than the tools coolant types machining tolerances also will help you to do better design and development. So keep in touch with MechHeart and feel free to add some comments here and share your knowledge with us.

0 Comments