Glass Manufacturing Process Step by Steps

Glass is a basic Engineering Material for most industries. In our day to day life also we use glass components in everywhere. Other than that Automobile, Ship Building, Aero Space applications also have glass components. Basically glass in every where. So, what is the glass manufacturing process? With this article we will discussed about the glass manufacturing process step by steps.

Raw Material for Glass Manufacturing

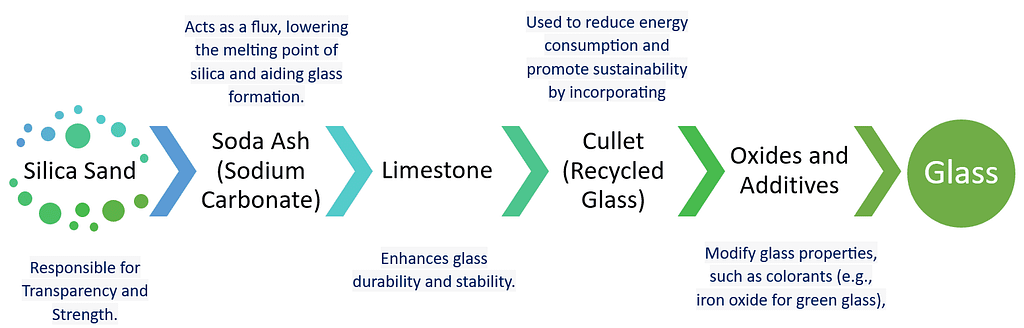

Basically, there are five types of raw materials needed for glass manufacturing. Each raw material gives different material properties for glass.

- Silica Sand

- Soda Ash (Sodium Carbonate)

- Limestone

- Cullet (Recycled Glass)

- Oxides and Additives

Each of these Raw Materials gives different properties for glass.

Types of Glass

There are different types of glass with different applications. The following table gives you a better understanding of glass types and their applications.

| Glass Type | Description | Common Application |

| Float Glass | Clear, flat glass produced by floating molten glass on a bed of molten metal, typically tin. | Windows, mirrors, architectural applications |

| Tempered Glass | Heat-treated to increase strength and safety by creating internal tension. | Car windows, shower doors, safety glass |

| Laminated Glass | Clear, flat glass is produced by floating molten glass on a bed of molten metal, typically tin. | Windshields, skylights, bullet-resistant glass |

| Frosted Glass | Treated to create a translucent appearance, providing privacy while allowing light transmission. | Partitions, doors, decorative windows |

| Tinted Glass | Contains additives to reduce transmitted light and heat, controlling glare and heat absorption. | Building windows, vehicle windows |

| Mirrored Glass | Has a reflective coating applied, creating a mirror-like appearance. | Mirrors, decorative items, architectural uses |

| Borosilicate Glass | Known for high thermal resistance and durability. | Laboratory glassware, cookware, lighting |

| Fiber Glass | Consists of fine glass fibers woven into a fabric or mat. | Insulation, reinforcements, composite materials |

| Optical Glass | Highly transparent glass with low dispersion, used in optical devices. | Lenses, prisms, optical instruments |

| Decorative Glass | Includes stained glass, fused glass, etched glass, used for artistic and decorative purposes. | Art installations, decorative windows |

Each glass type has different properties and uses in different applications.

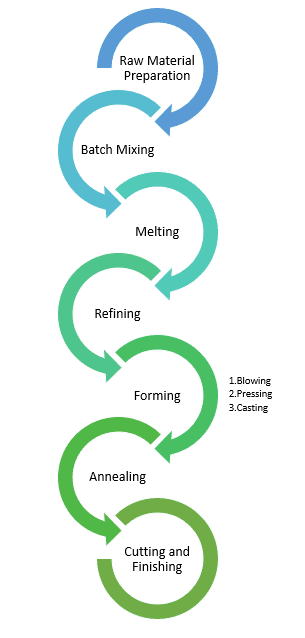

Glass Manufacturing Process Flow Chart

Glass manufacturing has several steps as shown in the below flow chart. These process steps are very common for most of the glass types. Some glass-like glass bottles are manufactured as batch production using blow molding. How every lab equipment and other custom designs are handmade products.

The 1st step is raw material selection. In the industry, operators typically mix all the materials to achieve the desired mixing ratio. This process is usually referred to as a batch mixing process. Metaling is the next process and it needs 15000 degrees of Celsius to get the molten stage of the mixture.

Different types of furnaces in the industry use active voice to achieve a temperature of 1500 degrees Celsius. Some fully automated furnaces normally we can find in glass bottle manufacturing plants.

After getting the melt mixture we need to remove the impurities or bubbles. The industry normally refers to this process as refining. The next process involves using the forming process to create glass shapes or final products.

Glass Forming Process

There are different types of glass-forming processes. Basically, this process will shape the molten glass into desired objects or forms. This is how basically you get different shapes of glass in the market.

- Blowing

- Pressing

- Casting

- Drawing

- Slumping

- Rolling

- Extrusion

The following are the applications of the Glass Forming Processes.

After the forming process, the formed glass needs to be cooled gradually. Then cutting and finishing processes are needed for better quality products. Quality control and packing are the final steps of the glass manufacturing process.

0 Comments