Additive Manufacturing Process-Advantages and Limitations

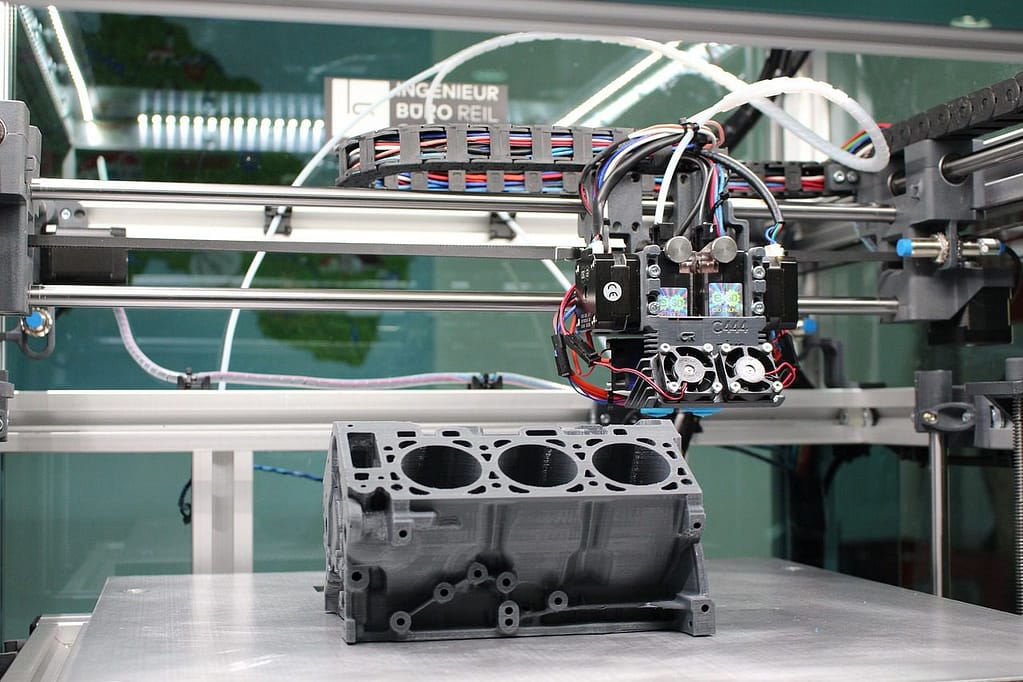

Additive manufacturing, or 3D printing, creates objects by adding layers of plastic or metal materials. Other than plastic and metals resin materials also use for additive manufacturing. It has revolutionized manufacturing, enabling complex shapes impossible with traditional methods. It’s used in aerospace, automotive, and healthcare, and is expected to grow with new materials and techniques. There are different types of manufacturing processes in this industry.

What is Additive Manufacturing (AM)

Additive manufacturing, or 3D printing, is a process of creating physical objects by adding material layer by layer. It allows for the creation of complex and intricate shapes. Those shapes are difficult or impossible to produce with traditional manufacturing methods. Additive manufacturing has applications in various industries, including aerospace, automotive, healthcare, and consumer products. Its benefits include faster production times, reduced waste, and the ability to create customized or one-of-a-kind objects. Technology evolves with new materials, techniques, and applications. It’s an exciting field with countless possibilities for the future of manufacturing.

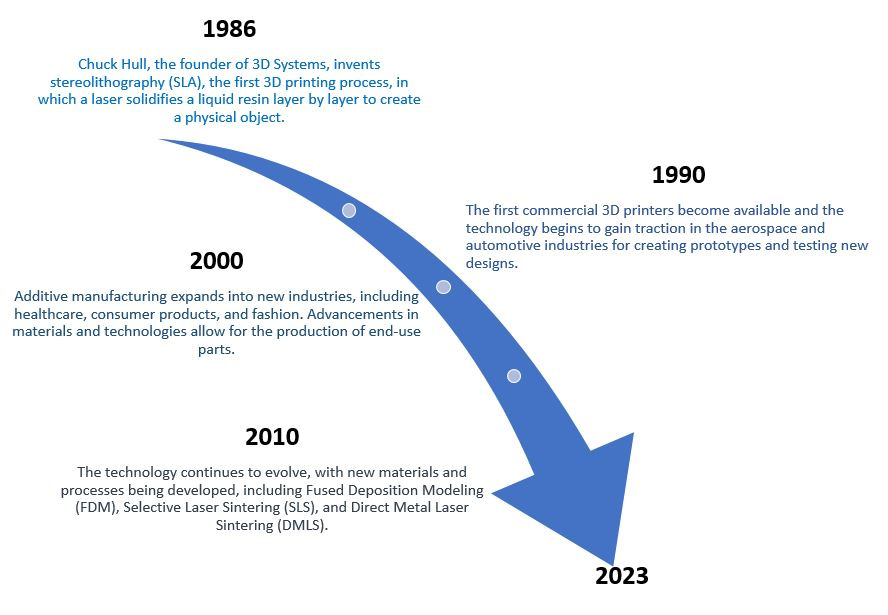

History of Additive Manufacturing

Additive manufacturing, also known as 3D printing, has its origins in the 1980s.

Types of Additive Manufacturing Processes

There are several types of additive manufacturing processes available.

- Material Extrusion:

- Fused Deposition Modeling (FDM)

- Vat Photopolymerization:

- Stereolithography (SLA)

- Digital Light Processing (DLP)

- Continuous Liquid Interface Production (CLIP)

- Powder Bed Fusion:

- Selective Laser Sintering (SLS)

- Selective Laser Melting (SLM)

- Electron Beam Melting (EBM)

- Direct Metal Deposition (DMD)

- Powder Bed Fusion (PBF)

- Multi-Jet Fusion (MJF)

- Binder Jetting:

- Binder Jetting

- Material Jetting:

- Material Jetting

- Directed Energy Deposition:

- Directed Energy Deposition (DED)

- Wire Arc Additive Manufacturing (WAAM)

- Laser Metal Deposition (LMD)

- Digital Beam Melting (DBM)

- Sheet Lamination:

- Laminated Object Manufacturing (LOM)

- Ultrasonic Additive Manufacturing (UAM)

- Other Processes:

- Continuous Fiber Reinforcement (CFF, FRFF)

- Robocasting

- Drop-on-Demand

- Bioprinting

- Cold Spray

- Magnetic 3D Printing

- Masked Stereolithography

- Hybrid Processes (combination with traditional manufacturing methods)

Fused Deposition Modeling (FDM)

FDM is a process that involves extruding a plastic filament through a heated nozzle to create a 3D object layer by layer. FDM is one of the most commonly used 3D printing techniques and is suitable for creating relatively simple objects.

Stereolithography (SLA

SLA uses a laser to cure a liquid resin, creating a 3D object layer by layer. This process can produce high-quality and intricate designs with a smooth surface finish.

Selective Laser Sintering (SLS)

SLS uses a laser to selectively fuse powdered material, such as plastic or metal, to create a 3D object. SLS is a versatile process that can create complex geometries and functional parts.

Digital Light Processing (DLP)

DLP uses a projector to cure a liquid resin, creating a 3D object layer by layer. DLP is similar to SLA but can create larger objects more quickly.

Binder Jetting

Binder Jetting uses a liquid binder to selectively bond powdered material, such as metal or sand, to create a 3D object. This process is fast and versatile but may result in lower resolution and surface quality.

Material Jetting

Material Jetting uses multiple inkjet print heads to selectively deposit materials, such as plastics or metals, layer by layer to create a 3D object. This process can produce high-resolution objects with a smooth surface finish.

Overall, the choice of additive manufacturing process depends on the application and the desired properties of the final product. Each process has its own advantages and disadvantages and is suitable for different types of objects and materials.

Materials Use for Additive Manufacturing

- Polymers/Plastics:

- Acrylonitrile Butadiene Styrene (ABS)

- Polylactic Acid (PLA)

- Polyethylene Terephthalate Glycol (PETG)

- Polypropylene (PP)

- Nylon

- Polyether Ether Ketone (PEEK)

- Polyvinyl Alcohol (PVA)

- Metals:

- Stainless Steel

- Aluminum

- Titanium

- Inconel

- Cobalt Chromium

- Copper

- Bronze

- Ceramics:

- Alumina

- Zirconia

- Silicon Carbide

- Glass

- Porcelain

- Composites:

- Carbon Fiber Reinforced Polymers (CFRP)

- Glass Fiber Reinforced Polymers (GFRP)

- Metal Matrix Composites (MMC)

- Ceramic Matrix Composites (CMC)

- Biomaterials:

- Bioinks for bioprinting (hydrogels, cell-laden materials)

- Polycaprolactone (PCL) for tissue engineering

- Calcium phosphate ceramics for bone implants

- Others:

- Wax

- Sand (for sand casting molds)

- Concrete and cementitious materials (for construction applications)

- Food-grade materials for culinary applications

Additive Manufacturing vs. Traditional Manufacturing

Additive manufacturing and traditional manufacturing are two distinct methods of producing physical objects. Overall, additive manufacturing (AM) offers flexibility and precision, while traditional manufacturing is efficient and cost-effective for mass production. Each method has pros and cons, and the choice depends on the manufacturer’s needs and the object being produced.

Advantages and Disadvantages

There are advantages and disadvantages of additive manufacturing processes compared to conventional manufacturing processes. Currently, this industry is more popular for rapid prototyping works. But some plastic industries like toy manufacturing have heavily used these processes.

The advantages and disadvantages of both methods are not absolute. They can vary based on the application and manufacturing process employed. Additionally, as technology continues to evolve, some of these disadvantages may be mitigated or eliminated.

Applications of AM

Additive manufacturing is a rapidly evolving technology with a wide range of applications across various industries. It allows for the creation of complex geometries, customized designs, and small-batch production, among other benefits.

Here are some common applications of AM

- Aerospace Applications

- Healthcare Applications

- Automotive

- Fashion

- Architecture and construction

- Education and research

- Consumer products

- Food Industry

- Rapid Prototypes in all industries

Additive manufacturing is versatile and adaptable to various applications. With ongoing technological advancements, the possibilities of this technology will expand further.

Clay Industry

Additive manufacturing has emerged as a game-changing technology in the clay industry, allowing for the creation of complex shapes and designs that were once impossible to achieve with traditional methods. With 3D printing, it is now possible to create ceramic objects with intricate geometries and internal structures, making it an attractive option for designers, architects, and artists.

Moreover, additive manufacturing enables clay manufacturers to reduce waste and increase sustainability, as it allows for the precise and efficient use of materials. As technology continues to evolve, it is likely to become an increasingly popular option for the production of ceramic objects, from sculptures and artwork to building facades and custom-made pottery. Overall, AM has the potential to transform the clay industry, enabling greater creativity, flexibility, and efficiency in the design and production of ceramic objects.

Future of Additive Manufacturing

The future of AM, also known as 3D printing, is full of promise and potential. As technology continues to evolve, it could revolutionize manufacturing across various industries. That will be creating new opportunities and be making production more efficient, sustainable, and customizable. One potential future development is the expansion of materials used in 3D printing, including metals, ceramics, and composites.

Additionally, advancements in speed and scale, as well as the integration of 3D printing with other technologies like robotics and artificial intelligence, could lead to even faster and more sophisticated manufacturing processes.

Further customization of designs and new applications of the technology, such as 3D printing of human tissue and organs. Moreover, 3D printing can potentially reduce waste, use sustainable materials and processes, and offer environmentally-conscious alternatives to traditional manufacturing. As a result, 3D printing is likely to become an increasingly attractive option for manufacturers looking to optimize their production processes.

Thank you for visiting Mechheart and reading our article on the advantages and limitations of AM processes! We hope this piece has provided you with valuable insights into the world of additive manufacturing and its implications for various industries.

0 Comments