Gear Design for Power Transmission

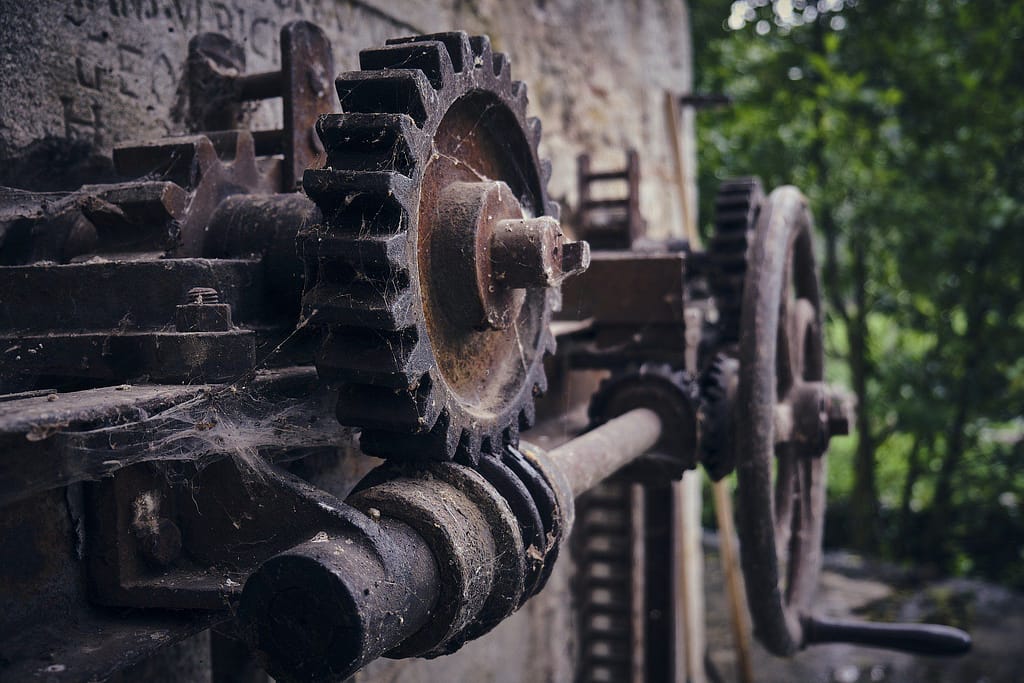

Gear is the main symbolic meaning of mechanical engineering. When we see a gear wheel, we will always think of mechanical engineering. Let’s get in touch about the gear wheels and how you can use them for your design. There are some gear design steps as well.

As a basic machine element, gears can be used for power transmission from the driving shaft to the drive shaft. There are several types of gear wheels under several calcification and categories. Gears are everywhere, and all machinery has some sort of a gear system, for instance, automobiles and every gearbox in industrial applications. That means you can also use a gear system for your design, and according to the requirement, you can go for standard gear wheels or similarly custom-made gear wheels.

Why do you use a gear system?

The main focus of the gear system is increasing the velocity or increasing the power in the power transmission system.

Advantages of gear drive

- The gear system is a high-efficiency, reliable, and compact layout.

- Gear transmission has an exact velocity ratio.

- After intermeshing the gear system no slipping in the transmission.

- Several Gear ratios and Power ratios in one compact gear system.

- Less maintenance due to lubricating usage

Gear Classification

The classification of gear is mainly based according to the gear axis, the peripheral velocity of the gears, the type of gearing, and the position of the gear teeth on the gear surface. Gear classification is very important when identifying the design requirement.

Types of Gear

Under the gear classification, there is a lot of variety of gears for full fill the various design criteria. You can go for the following common types of gears,

- Spur Gears

- Single Helical Gears

- Double Helical Gears

- Rack and Pinion

- Planetary Gears

- Worm and Wheel

- Bevel Gears

- Non–Circular Gears

- Ratchets

Diversity of the Gears

The diversity of the gear wheels is very high due to the following factors, when you buy or manufacture gear wheels you have to consider the following factors.

- Gear Type

- System of Measurement (Inch/Metric)

- Shaft Diameter

- Pitch Size

- Pitch Diameter

- Pressure angle

- Number of Teeth

- Face With

- Bore Type

- Surface Roughness

- Teeth Heat Treatment

- Hub with Hub Diameter

- The material of the Gear

Are there any standards for gear systems? Yes, there are several standards for gears as well, such as AGMA, JIS, DIN, ISO and etc. But because of the diversity and several standards, you have to face the difficulty of finding the desired gear wheel to replace the existing machine. But if you design something by yourself it is not a problem because you know the specification of the gear wheel when you need to replace it. However, If you don’t have the speciation of the existing gear profile data you have to measure the gear wheel

How to measure the existing gear wheel

Methods for measuring the gear wheel dimensions

- Measure the gear size using a pin or boll with the micrometer

- Measure the tooth size by using a tooth caliper

- Helix inspection of Helical Gears

- Runout inspection (use to measure the backlash) by using a dial gauge

- Profile inspection (Trace the gear teeth profile) for inspection the gear teeth profile

- Pitch inspection can be done by using a pitch comparator or angular indexing.

- Double flank or Single Flank test.

Buy or Manufacture?

As a mechanical engineer, you have to think about cost-effective methods and cost-effective ways for new designs, therefore, more suitable to go for standard-size gear wheels and available gear wheels rather than manufacture special gear wheels. Because if you go for a special gear design or noncircular gear design it will be more costly because you may have to go for the CNC Wire cut or EDM manufacturing process.

The process of Gear Manufacturing is affected by your design

- Machining (With form cutters, gear milling, broaching, Gear Hobbing )

- Finishing operation – (Gear Shaving, Burning, Grinding, Lapping, Honing)

- Casting

- Stamping

- Coining

- Cold Drawing

- Rolling

- Extrusion

- Powder metallurgy

- Injection Molding

What Gear Material do You need to use for your design

There is a huge variety of gear materials that we can use in our design. Selection is depending on the requirement and the application. As an example, if you need to build a prototype no need to go for high strength and highly reliable materials, then you can go for a plastic gear wheel or a 3D printed one. For instance, the followings are the common gear wheel materials that you can find in the market.

- Gary cast iron

- Nodular and ductile cast iron

- Carburizing steel

- Nitride steel

- Bronze

- Plastics or reinforced laminates

How to design your own gear system

The answer is there are two ways to do this, you can go for full manual calculation, which means you should have good mathematical knowledge and calculation capability regarding gear calculation. Another option is you can go for CAD software which is the most common and easiest way to do the design because CAD software is provided standard sizes of gear wheels, selection of a number of gear teeth, pressure angle, width, and bore size, and those software’s have motion and simulation capabilities. If you go for CAD software you have some facilities,

- simulation (calculate the braking load with several materials then you can choose the best material for your design)

- Motion facility (Normally we cannot use one gear, definitely it is a gear system then motion is very important to identify the way of gear system is working)

So, these are the basic knowledge you should have when you plan to do a gear system design, and really appreciate your taking the time to read the article. Feel free to add some comments here and share your knowledge with us.

0 Comments