Permanent Mold Casting Vs Expandable Mold Casting

Casting is the main manufacturing process manufacturing industry. Casting processes are various according to the mold type. There are mainly two types of casting processes according to the mold type. Which are Permanent and Expandable Mold Casting and expendable mold casting. Permanent and Expendable Mold Casting processes are commonly used in the industry according to the product requirement. Anyway, both methods have advantages and disadvantages.

Expendable Mold Casting

In Expendable mold casting, the casting user has to break the mold to remove the casting. Therefore, one mold needs for one casting. To make the mold reusable materials like sand, plaster, ceramic, and other refectory materials with binders can use. In this method, one mold requires one casting, therefore this method is preferred for small quantities. There are two types of patterns used for this casting process.

- Removable patterns (Wood, Plastic & Metal)

- Disposable Patterns (Polystyrene)

The followings are examples of expendable mold casting.

Types of Expendable Casting

- Sand Casting

- Shell Casting

- Evaporative Pattern Carting

- Plaster Casting

- Ceramic Casting

- Investment Casting

Permanent Mold Casting

The Casting calls as bard mold casting as well. This mold is made by using high resistance to erosion and thermal fatigue materials such as,

- Cast Iron

- Steel

- Bronze

- Graphite

- Refectory metal alloys

To produce the internal cavity of the permanent mold casting, cores are made of using several materials such as;

- Oil bonded or resin-bonded sand

- Plaster

- Graphite

- Gray iron

- Low carbon steel

- Hot work die steel.

To increase the life of permanent mold surface of the mold cavity coated with refractory slurry (Solidum Silicate or Clay) or sprayed with graphite every few castings. There are several casting processes such as;

Types of Permenent Mold Casting

- Slush Casting

- Pressure Casting

- Die Casting

- Centrifugal Casting

- Squeeze Casting

- Semisolid Casting

Permanent mold casting is good for mass production because one mold can use several times of production. The initial investment for mold making is very high compared to the expendable mold casting process. However, the followings are some of the advantages of this process.

Advantages

- Good surface finish

- Closed dimensional tolerance

- Good mechanical properties

- High production rate according to applications

- Uniform properties

- Uniform Dimensions

Common Permenanet Mold Casting Materials

- Aluminum

- Magnesium

- Copper Alloy

- Gray Iron

Applications

- Automotive Pistons

- Automotive Cylinder Head

- Connecting Rods

- Gear Blanks

- Kitchen wares

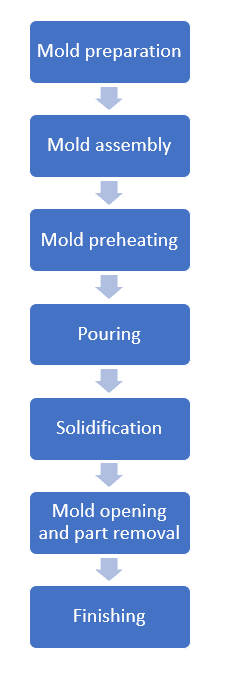

Process Steps of Permanent Mold Casting

The mold casting technique is a metal casting method that uses reusable molds. The most typical method is to fill the mold using gravity, however gas pressure or a vacuum can also be utilized. Slush casting is a variation on the traditional gravity casting method that generates hollow castings. There are several steps for Permanent Mold Casting

In conclusion, permanent mold casting stands as an efficient and reliable manufacturing process, offering numerous advantages such as cost-effectiveness, high dimensional accuracy, and consistent production quality. Its ability to withstand high temperatures and repeated use makes it ideal for producing complex and intricate parts with excellent surface finish. By harnessing the power of this casting process, manufacturers can achieve streamlined production, reduced waste, and accelerated time-to-market. Embracing this innovative technique opens doors to limitless possibilities in various industries, paving the way for superior product performance and customer satisfaction.

Really appreciate, your taking the time to read the article about Ergonomics. So keep in touch with MechHeart and feel free to add some comments here and share your knowledge with us.

0 Comments