Engineering Materials and Their Properties

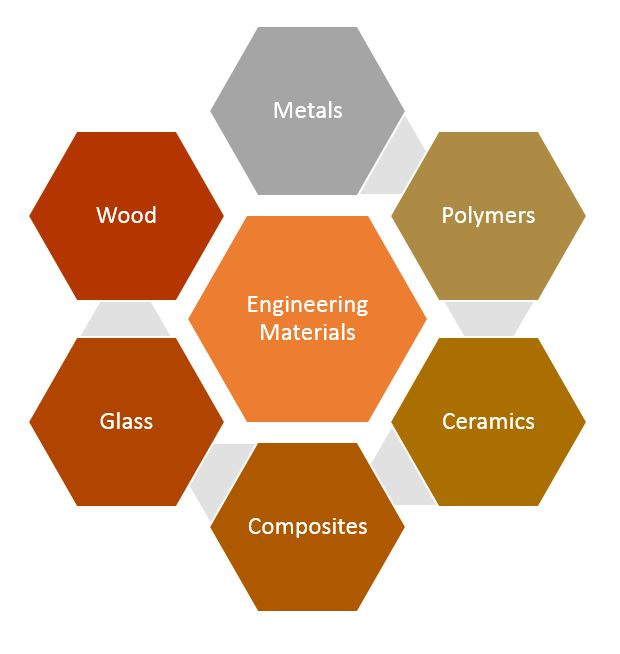

Engineering materials are the building blocks of modern society and a critical component of countless products, structures, and machines. From metals and ceramics to polymers and composites, the range of materials available to engineers is vast and constantly evolving. Understanding the properties, strengths, and limitations of each type of material is key to designing and constructing effective and efficient engineering solutions. In this article, we will explore the fascinating world of engineering materials and their applications in various industries and technologies.

What are Engineering Materials

We can simply say that materials used for engineering works are engineering materials. But when you are selecting materials for your engineering works you have to think about their properties as well. Those properties are mechanical properties, electrical, and chemical properties. Depending on the applications material properties requirements can be changed.

Basically, there are mainly three types of engineering materials.

- Metals

- Polymer

- Ceramic

Using these basic three types of materials we can make Composite materials. Anyhow in the modern world, there are various types of materials.

Types of Metals as Engineering Material

Metals are very common engineering materials. Metal alloys are more popular in various industries. Combining one or more metallic or nonmetallic materials alloys can be made. Metal alloys have good material properties compared to pure metals.

Mainly there are three types of Metals.

- Ferrous Metals

- Non-Ferrous metals

- Alloys

Ferrous Metals

Mainly composed of iron (Fe) and carbon (C). Ferrous metals are widely used in various industries due to their desirable mechanical properties, availability, and relatively low cost. However, they are prone to rust and corrosion, necessitating protective measures such as coatings, galvanization, or stainless steel alloys to enhance their resistance to environmental degradation.

Following are common examples of Ferrous Metals

- Iron (Fe): Pure iron is a soft and ductile metal

- Steel: Steel is an alloy of iron and carbon

- Cast Iron: Cast iron is an alloy of iron, carbon, and silicon

- Wrought Iron: Wrought iron is a very low-carbon alloy of iron

Non-Ferrous metals

Non-ferrous metals are metals that do not contain iron or have very low iron content. These metals are known for their lightweight, corrosion resistance, electrical conductivity, and malleability. They find applications in a wide range of industries, including electronics, aerospace, construction, automotive, and more.

Here are some examples of non-ferrous metals:

- Aluminum (Al): Aluminum is a lightweight metal with excellent corrosion resistance.

- Copper (Cu): Copper is highly conductive and has excellent electrical and thermal properties.

- Brass: Brass is an alloy of copper and zinc.

- Bronze: Bronze is an alloy of copper and other elements.

- Nickel (Ni): Nickel is a versatile metal with excellent corrosion resistance and high-temperature strength.

- Titanium (Ti): Titanium is a lightweight metal with a high strength-to-weight ratio and excellent corrosion resistance.

- Zinc (Zn): Zinc is commonly used as a protective coating for steel (galvanization) to prevent corrosion.

Alloys for Engineering Works

Alloys are metallic substances that are composed of two or more elements, with at least one of them being a metal. These are created by combining metals or metals with non-metallic elements to enhance their properties or provide new characteristics that are not present in the individual elements. Alloying can alter properties such as strength, hardness, corrosion resistance, electrical conductivity, and melting point.

Here are some examples of Alloys

- Steel

- Stainless steel

- Aluminum alloys

- Brass

- Bronze

- Cast iron

- Titanium alloys

- Nickel alloys

- Copper alloys

- Zinc alloys

- Magnesium alloys

- Lead alloys

- Tin alloys

- Gold alloys

- Silver alloys

Metals alloys are very popular for engineering designs due to their excellent engineering properties. These materials are used in different manufacturing processes such as gear manufacturing, automotive, aerospace applications, and all other manufacturing tasks.

Polymers Materials as Engineering Materials

Polymer materials are versatile engineering materials widely used in various industries. They offer flexibility, lightweight properties, corrosion resistance, and electrical insulation. Polymers can be molded into complex shapes, making them suitable for intricate components. However, they may have lower strength compared to metals and temperature limitations. Nevertheless, their advantages make them valuable in applications such as automotive, aerospace, electronics, and packaging. With ongoing advancements, engineers continue to explore and optimize polymer materials to meet evolving design requirements and drive innovation in diverse sectors.

Following are some examples of polymer materials

- Polyethylene (PE)

- Polypropylene (PP)

- Polyvinyl chloride (PVC)

- Polyethylene terephthalate (PET)

- Polystyrene (PS)

- Polyurethane (PU)

- Polyvinyl acetate (PVA)

- Polytetrafluoroethylene (PTFE)

- Nylon (Polyamide)

- Acrylic (Polymethyl methacrylate, PMMA)

- Polybutadiene (PBD)

- Silicone (Polydimethylsiloxane, PDMS)

- Ethylene-vinyl acetate (EVA)

- Polyphenylene oxide (PPO)

- Polycarbonate (PC)

Ceramics Materials

- Alumina

- Zirconia

- Silicon carbide

- Silicon nitride

- Porcelain

- Glass

- Ferrites

- Clay

- Refractory materials

- Cement

Composites Materials

- Carbon fiber-reinforced polymers (CFRP)

- Glass fiber-reinforced polymers (GFRP)

- Aramid fiber-reinforced polymers (AFRP)

- Natural fiber composites

- Metal matrix composites (MMC)

- Ceramic matrix composites (CMC)

- Particle-reinforced composites

- Fiber-reinforced concrete

- Sandwich panels

- Plywood

Material Properties of Engineering Materials

When you are going to select materials for your design or manufacturing processes you need to think about your design or manufacturing requirement. Here are some basic material properties.

- Density: Mass per unit volume of a material.

- Elasticity: Ability of a material to deform under stress and return to its original shape when the stress is removed.

- Hardness: Resistance of a material to permanent deformation or indentation.

- Strength: Ability of a material to withstand an applied force without breaking or deforming.

- Ductility: Ability of a material to undergo plastic deformation before fracturing.

- Brittleness: Property of a material that fractures or breaks easily without significant deformation.

- Stiffness: Ability of a material to resist deformation under an applied load.

- Toughness: Energy absorption capacity of a material before fracturing.

- Thermal Conductivity: Ability of a material to conduct heat.

- Electrical Conductivity: Ability of a material to conduct electricity.

- Thermal Expansion: Change in dimensions of a material due to temperature variations.

- Corrosion Resistance: Ability of a material to withstand chemical reactions with its surroundings.

- Magnetism: Property of a material to be attracted or repelled by a magnetic field.

- Refractive Index: Measure of how light propagates through a material.

- Melting Point: Temperature at which a solid material transforms into a liquid state.

- Boiling Point: Temperature at which a liquid material transforms into a gaseous state.

- Coefficient of Friction: Measure of the resistance to sliding between two surfaces in contact.

- Creep: Time-dependent deformation of a material under a constant load.

- Fatigue Resistance: Ability of a material to resist failure under cyclic loading.

- Wear Resistance: Ability of a material to withstand erosion or degradation due to contact with other surfaces.

Advance Engineering Materials

Advanced engineering materials play a crucial role in modern technology and innovation. Moreover, these materials are specifically optimized to deliver certain performance characteristics, such as increased strength, flexibility, and corrosion resistance, which often surpass those of traditional materials. Additionally, they are specially designed to withstand extreme environments, including space and aviation technologies, as well as other demanding applications.

Furthermore, advanced engineering materials come in various forms, including metals, ceramics, polymers, and composites. Notably, these materials can be intricately engineered at the atomic and molecular levels to create unique and highly desirable properties. Importantly, this ability to manipulate materials at such small scales opens up exciting possibilities.

One of the most fascinating aspects of advanced engineering materials is their potential to create smaller, lighter, and more efficient products that offer improved performance and durability. Consequently, these materials present an opportunity to address some of the world’s most complex challenges and propel human progress forward.

Examples for Advance Materials

- High-Performance Ceramics

- Graphene

- Biomimetic Materials

- Smart Materials

- High-Temperature Alloys

- Nanomaterials

- Shape Memory Alloys (SMAs)

- Advanced Composites

Where you can buy

There are various places where engineering materials can be purchased. One option is specialized industrial suppliers or manufacturers who cater to specific industries and offer a wide range of advanced engineering materials. Online marketplaces can also be a convenient option for purchasing engineering materials, with many suppliers offering a wide selection of materials to choose from. It is important to research and identify reliable suppliers who offer high-quality materials that meet specific requirements.

However, you may need traceable materials for your engineering work. So you need to check the traceability reports before buying a material lot.

Basic Forms of Materials

Metals exist in various basic forms, each with its own characteristics and applications. Here are some of the basic forms of metals.

0 Comments